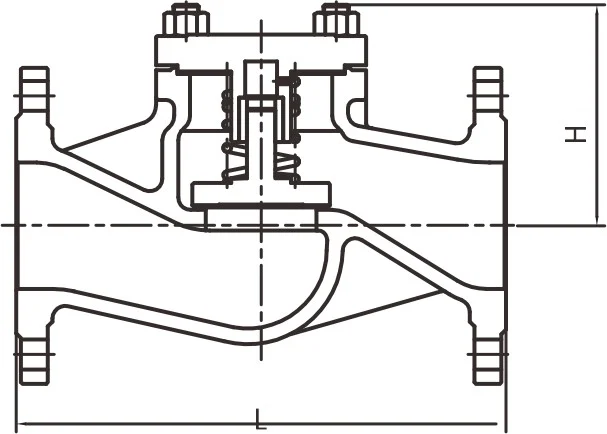

A lift check valve is a type of check valve whose primary function is to allow only one-way flow and prevent backflow. It primarily consists of a valve body, disc, seat, and guide sleeve. Made from a variety of materials, these valves are typically made of durable materials such as stainless steel, cast iron, and carbon steel, designed to withstand high pressures, extreme temperatures, and high speeds. They are commonly used in the petroleum, chemical, and power industries to ensure stable system operation.

How Lift Check Valves Work

At the beginning of this article, we mentioned that lift check valves only allow one-way flow. Let’s explore how they achieve this remarkable feat.

Forward Flow: When fluid flows in the desired direction, the pressure generated by the medium acts on the underside of the disc. As the pressure gradually increases, it overcomes the weight of the disc (and sometimes the force of a spring), pushing the disc upward along the vertical centerline of the valve body. This forces the tapered disc off the seat, opening the valve and allowing the medium to flow smoothly through the pipeline.

Reverse Flow: When reverse flow occurs, the disc is subjected to pressure from the reverse-flowing medium, while the disc’s own weight also acts (some are assisted by a spring). Under these dual forces, the disc quickly returns to the seat, sealing tightly and closing the valve, effectively blocking reverse flow and ensuring consistent unidirectional flow in the pipeline.

Factors to Consider When Selecting a Lift Check Valve

This small valve holds great secrets. The world of valves is diverse and dazzling. How do I choose the most suitable valve? Do I really need a lift check valve? These questions may have crossed your mind and become troubling questions. Don’t worry, we’ll analyze them carefully.

Application Scenario and Operating Parameters

Media Type: Specify whether the fluid is liquid, gas, or slurry. Lift check valves are generally suitable for clean media. If the media contains impurities or is abrasive, their suitability needs to be evaluated.

Operating Pressure and Temperature: The selected pressure and temperature ratings must meet the system’s operating conditions, including potential peak pressures and test pressures.

Valve Materials

Valve Body Material: Select based on the corrosiveness, temperature, and pressure of the media. Common materials include cast iron, carbon steel, stainless steel, and copper.

Internal and Seal Materials: The sealing surface material (such as PTFE, rubber, or metal) must be compatible with the media and have corrosion and high-temperature resistance comparable to the valve body material.

Sealing Performance and Flow Resistance Requirements

Lift check valves offer better sealing than swing check valves, but they also have greater flow resistance. If the system is sensitive to pressure drop, a trade-off between sealing and flow efficiency must be considered.

Space and Installation Conditions

Ensure adequate installation and maintenance space around the valve. Observe installation spacing requirements (e.g., ≥5 pipe diameters downstream of elbows) to minimize turbulent flow.

Special Application Considerations

For pump inlets, if the pipeline is vertical and the media flows from bottom to top, consider using a foot valve (a special lift check valve).

When the media pressure or kinetic energy is low, be aware that the disc may not fully open or may flap. If necessary, a spring-assisted silent lift check valve may be used.

Daily Maintenance of Lift Check Valves

To ensure a long valve life, daily maintenance is essential. We can ensure proper operation and extend its service life by taking the following measures.

Appearance Inspection

Cleaning the Valve Surface: Regularly clean the valve’s exterior to remove dust, oil, rust, and other debris. Use a clean, soft cloth, brush, or a dedicated cleaning agent. Also, ensure the valve’s nameplate and markings are clear and intact. The nameplate contains important information such as the valve model, specification, and pressure rating, which is crucial for valve maintenance and troubleshooting.

Checking Connections: During each inspection, check the bolts connecting the valve to the pipeline for looseness. Tighten them to the specified torque using an appropriate wrench. Also, check the integrity of the gaskets at the valve connections. Damaged gaskets are a common cause of valve leakage.

Valve tightness inspection

Checking for External Leakage: Check the valve stem seal for any leakage. Apply a small amount of leak detection fluid (such as soapy water) around the valve stem to observe for bubbles. If bubbles are present, there’s a problem with the valve stem seal, which requires prompt attention.

Valve Operation Inspection

Check the Disc’s Lifting Flexibility: Regularly check whether the disc can rise and fall freely within the valve body. This can be determined by observing the disc opening and closing during fluid flow. If the disc is not rising and falling freely, it could be due to foreign matter trapped between the disc and the body, wear or deformation of the guide sleeve, or other factors. These factors require prompt removal of the foreign matter or repair or replacement of the relevant components.

Check the Sealing: With the valve closed, check for leakage. This can be done by measuring pressure changes at the valve outlet or applying a leak detector. If leakage is detected, inspect the sealing surface between the disc and seat for damage or corrosion. If any problems are detected, resurface the sealing surface or replace the relevant components.

Summary

Lift check valves, with their excellent sealing performance, compact structure, and sensitive operation, play an important role in industrial piping systems. If you’re still hesitant about purchasing a lift check valve, please contact us. Newton is a good choice.