Comprehensive Solutions for Steam and Thermal Energy Systems

Steam and Thermal Energy System Solutions

Temperature and Pressure Reducing System

Condensate Drainage System

Condensate Recovery System

Control Valve:

It can accept the control signal sent by the controller to adjust the flow and pressure of the medium in the pipeline.Bellows Sealed Globe Valve:

The bellows are used as sealing elements to compressand release the bellows to realize the switch function of the valve.

Y Strainer :

It can filter the impurities in the pipe.

Steam Trap Station :

It integrates the advantages of globe valve,steam trap and filterto realize the function of steam resistance and drainage, which greatly

save procurement cost and installation space.

Cylinder :

It can distribute steam to where it is needed.

Inverted Bucket Steam Trap :

It works based on the difference of vapor and liquid density,drain the condensed water in the pipe.

Pump :

The Pump uses high pressure steam or gas as the power source,

which can realize the recovery and reuse of high and low pressure

condensate connected to use.

Pressure Reducing Valve :

Through wide range of manual setting decompression range,

It can effectively prevent the system from being damaged by high

pressure, so as to ensure safety.

350

Employees

37

Engineers

75000㎡

Area

2000㎡

Laboratory

1,000+

Customers

26

Years

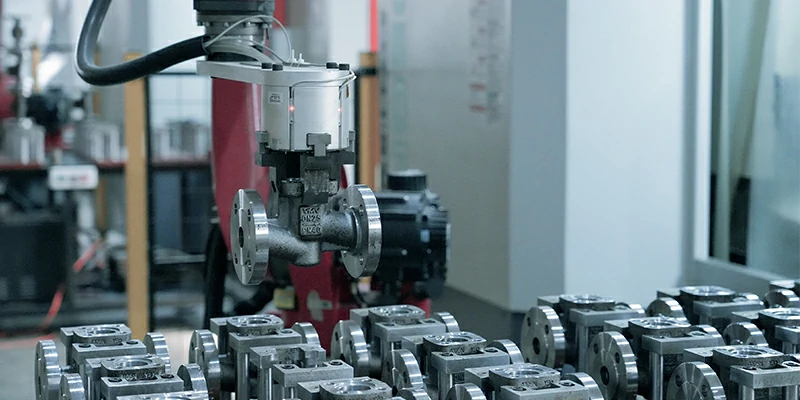

Main Valve Series

Focus on details and quality, do valuable valves.

Applications

We have rich experience in various industries, offering products and solutions.

Industry

Medium

Heating

Chemistry

Electricity

Pharmacy

Food

Tobacco

Printing

Air Conditioning

Shipbuilding

Steam

Thermal Oil

Ammonia Gas

Liquid Ammonia

Ethylene Glycol

Fatty Acid

Aases

Precious Fluids

ETC...

SECURE THE SYSTEM, SAVE THE ENERGY!

VMV NEWTON, YOUR BEST PARTNER!

VMV Newton was founded in 1998 and committed to providing comprehensive solutions for steam and thermal energy systems.

Not just products service, but from the site survey, energy saving diagnosis, full range of product development, project landing, operation monitoring to from system solutions, all follow the principle of sustainable development.

We have also qualified with CE PED 0036, ISO9001, ISO14001, ISO45001, EAC, TS A1, CCS certificates etc.

Why Choose VMV

VMV is committed to provide customers with the best advice, superior quality, highest reliability, as well as the reliable service.

Smart Production Management

- Standardized production process

- High precision machining capability

- Environment and sustainable development

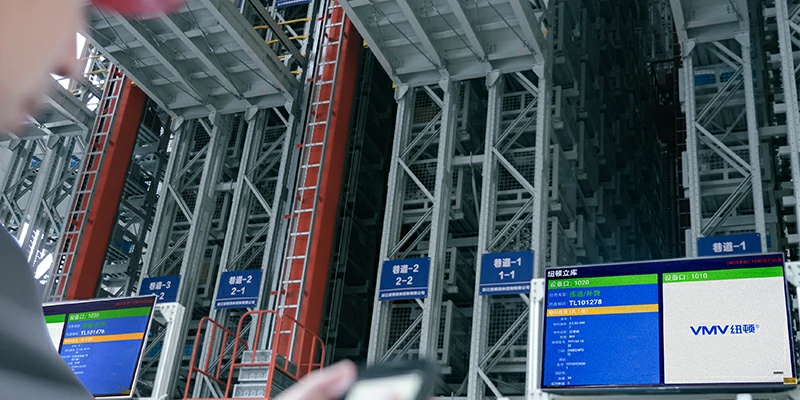

Complete Inventory WMS System

- Quick response delivery

- Accurate data of spare parts and valves

Strict Quality Control

- Mechanical performance testing laboratory

- Full process inspection

Specialized Technical Support

- Technical research and development

- Offer the best possible solutions

Latest News

The core theme of VMV is closely connected to Valve (Valve), doing our best (Max), helping customers succeed (Victory).