In heating, temperature control, refrigeration, and even the entire industrial fluid automation field, the ball-type linear control valve is a commonly used and indispensable fluid control component. This control valve primarily regulates the pressure, flow rate, temperature, and level of steam and other fluids by changing the throttling area between the valve core and the valve seat.

Common problems with ordinary ball-type linear control valves include: difficult valve seat disassembly and assembly, packing wear and leakage, poor adjustment accuracy, poor sealing (especially prone to jamming under high temperature conditions), excessive vibration and noise, valve stem breakage or detachment, and large leakage. These problems cannot meet operational requirements and, in severe cases, can even lead to emergency shutdowns, causing significant losses to users.

If you are currently facing problems caused by ordinary ball-type linear control valves, then you may want to take a look at Newton’s V8000 Series Control Valve.

The V8000 model effectively solves the above problems and possesses the following characteristics:

- Excellent high pressure differential stability

- Durable seals under high temperature operation

- Convenient and quick on-site valve maintenance

- Fast response speed

- VMV valves can be equipped with pneumatic diaphragm actuators or electric actuators depending on the user’s site conditions

- High adjustment accuracy and low leakage

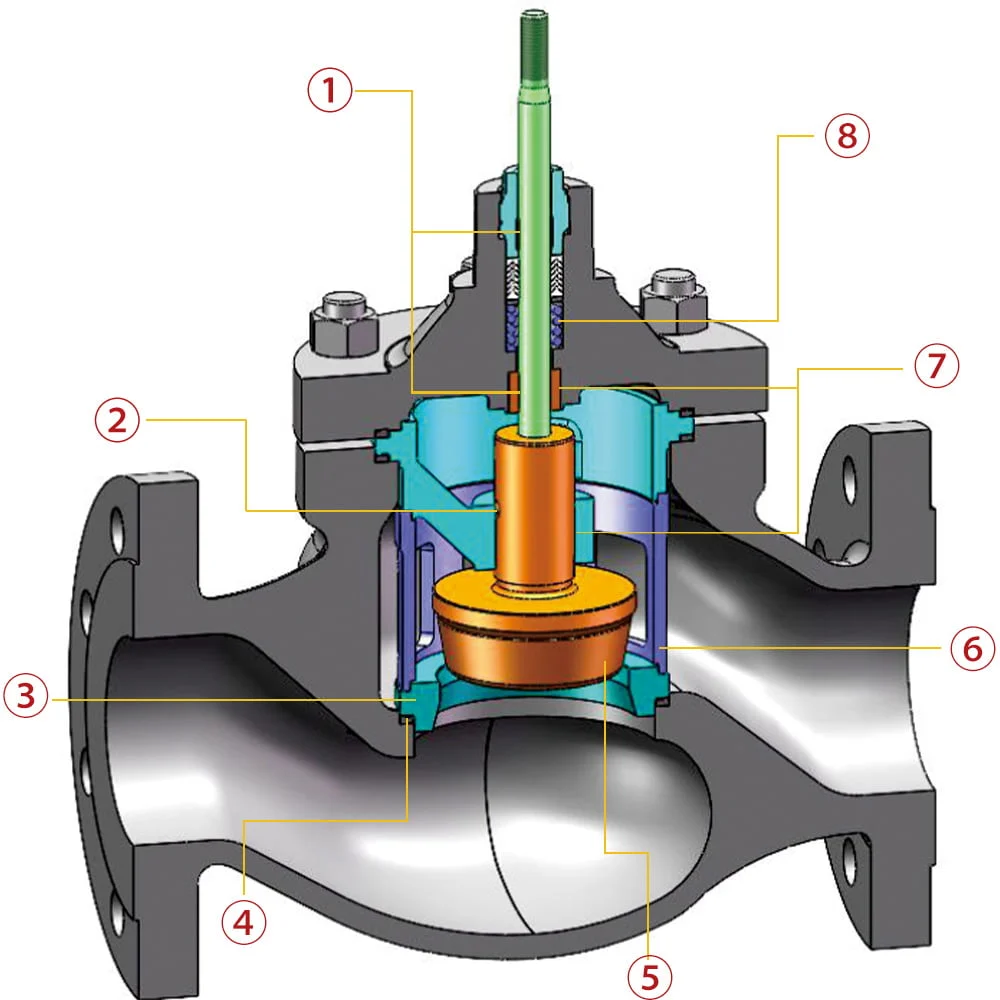

V8000 Series Control Valve Structural Advantages

① Dual-Guided Stem Structure: Maintains coaxiality between the packing and valve stem, preventing abnormal packing wear caused by eccentricity, thus significantly extending packing life.

② Threaded + Pin Connection Structure: The valve plug and valve stem are tightly connected by threads and pins, with no relative movement clearance, effectively preventing valve stem fatigue and breakage caused by relative oscillation between the valve plug and valve stem.

③ Top-Pressure Seat Structure: By loosening the valve cover bolts, internal valve components can be disassembled one by one, facilitating quick on-site maintenance and component replacement, saving users time on seat replacement and internal maintenance.

④ Gasket Quantitative Compression Structure: Prevents excessive gasket compression, achieving a durable seal and avoiding external leakage.

⑤ Single-Seat Sealing Structure: Low leakage, excellent sealing performance, and can meet Class V and higher leakage requirements for extended periods.

⑥ Elastic Pressure Cage Compensation Structure: Under high-temperature conditions, the pressure cage absorbs axial displacement caused by high temperature and converts it into radial elastic deformation, preventing gasket or internal valve components from failing due to thermal stress deformation.

⑦ Dual-guided valve plug structure: The valve plug operates smoothly, is less prone to vibration and jamming, and ensures higher adjustment accuracy.

⑧ Spring-loaded stuffing box structure: Provides continuous and stable

compression force to the packing, enabling the packing to automatically compensate for wear during use and achieve long-term stable sealing.

V8000 Series Control Valve Advantages

Low-Noise Valve Spool Structure

This design reduces the media flow rate, thereby minimizing the erosion of the valve spool and seat caused by high flow rates, extending the valve’s service life. It also reduces noise, minimizing environmental noise pollution. Vibration reduction prevents high-frequency vibration from damaging internal valve components, improving regulation accuracy and service life.

Multi-Stage Pressure Reducing Valve Spool Structure

Suitable for high pressure differential conditions, this structure reduces media flow rate, minimizing the erosion of the valve spool and seat caused by high-speed flow, thus extending the valve’s service life. It also reduces noise, minimizing environmental noise pollution. Furthermore, this structure reduces vibration, preventing high-frequency vibration from damaging internal valve components, improving regulation accuracy and service life.

Pilot-Operated Valve Spool Structure

This valve spool structure provides both regulation and shut-off functions, exhibiting excellent sealing performance under high-temperature (>230°C) operating conditions, ensuring a long-term sealing rating of V or higher. In addition, this structure effectively reduces vibration, preventing high-frequency vibration from damaging valve components, thereby improving regulation accuracy and service life.

If you’ve read the introduction to the V8000 Series Control Valve and feel it’s the valve you’re looking for, please contact us. Newton is always ready to serve you.