Introduction

In industrial pipeline systems, bellows gate valves play an important role in the safety and operating efficiency of equipment. An accurate selection can not only extend the service life of the valve, but also effectively avoid system failures and save a lot of maintenance costs. How to select the most suitable bellows gate valve according to working conditions? This article will take you to deeply analyze the key elements in the selection process, so that you can still make appropriate decisions when facing various complex conditions.

Factors to consider when selecting bellows gate valves

Usually we need to consider many factors when purchasing a bellows gate valve, which can be summarized as the following aspects.

- Connection size and installation space requirements

Pipeline connection method, structural length, installation space and weight limit, etc.

- Nature of working medium

Working pressure, working temperature, corrosion performance, whether it contains solid particles, whether the medium is toxic, whether it is flammable and explosive, the viscosity of the medium, whether there are degreasing, surface polishing and cleanliness requirements.

- Additional requirements for products

Additional requirements for the reliability and service life of bellows valve products, the material, brand, service life of bellows and actuators.

- Product adaptability

Purpose, operating conditions and operation control methods of the selected bellows valve

How to choose a suitable bellows gate valve

1.Installation size and external dimension requirements

Detailed requirements:

Nominal diameter and nominal pressure: based on the operating flow requirements.

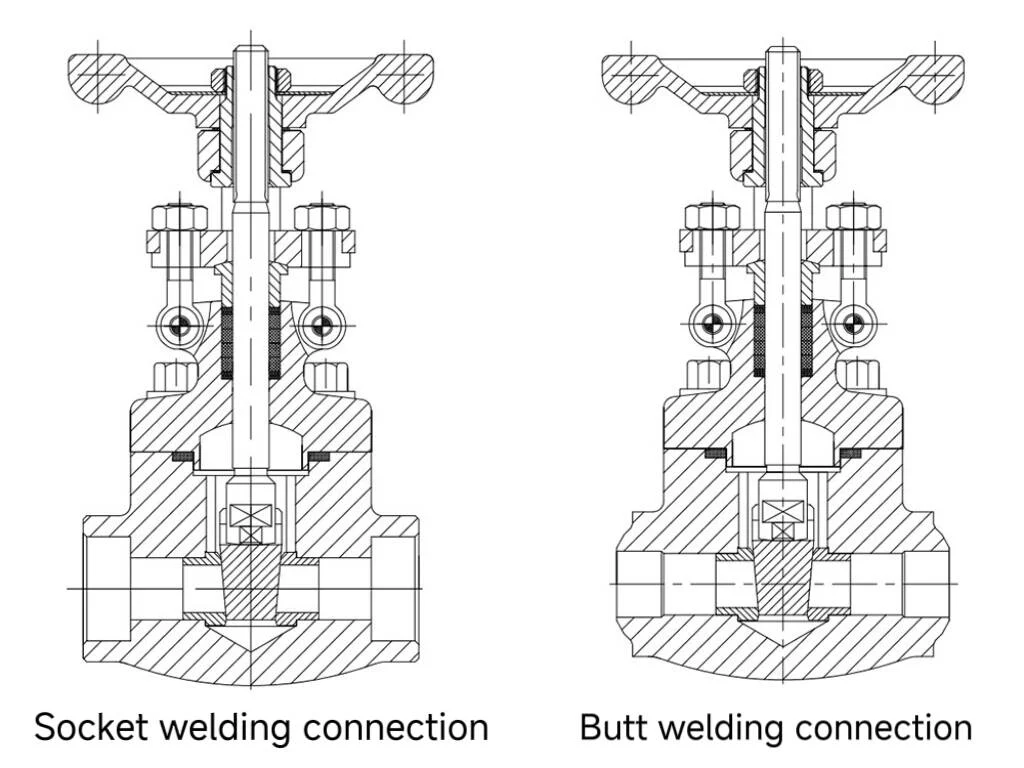

Connection method: flange, welding, etc.

External dimensions: space limitations.

Specific suggestions:

Diameter selection: According to the pipeline diameter and flow requirements, avoid valves that are too large or too small to affect system stability. For example, the sewage pipes of chemical plants may need to choose a slightly larger valve diameter to ensure that the flow is not restricted.

Connection method: flange for large diameter/high pressure, thread, butt welding, socket for small diameter.

Space limitations: adapt to the installation space.

2.Nature of the working medium

Detailed requirements:

Working temperature: medium and high temperature, low temperature.

Corrosiveness: corrosion-resistant material.

Specific suggestions

Working temperature: For low temperature, choose stainless steel materials such as LCB, CF8, CF8M, etc. For medium and high temperature, choose stainless steel materials such as WCB, WC6, WC9.

Corrosive media: Choose stainless steel materials such as CF8 and CF8M, and special media choose titanium alloy, Hastelloy, Monel alloy, duplex stainless steel and other materials.

3.Reliability and service life

Detailed requirements:

Reliability: The product undergoes strict factory inspection.

Bellows sealing: The bellows and its components should be sealed, and the bellows components should not leak when tested under a pressure of 0.6MPa.

JB/T 10507-2005

| Valve specifications | ||

| Nominal pressure MPa | Nominal diameter mm | Gate times |

| PN≤14.0 | DN≤50 | 2000 |

| 50<DN≤100 | 2000 | |

| DN>100 | 1000 | |

| PN>14.0 | DN≤50 | 2000 |

| 50<DN≤100 | 1000 | |

| DN>100 | 1000 | |

Specific Requirements:

Reliability: Product factory inspection, through API598, GB/T26480 and ISO15848 emission test.

Service Life: Select the appropriate nominal pressure and nominal diameter according to the working conditions. The material of the bellows is conducive to increasing the service life of the valve.

4.Application and Control Method

Detailed Requirements:

Application: Industry, Chemical Industry, etc.

Control Method: Manual, Electric, Pneumatic.

Specific Requirements

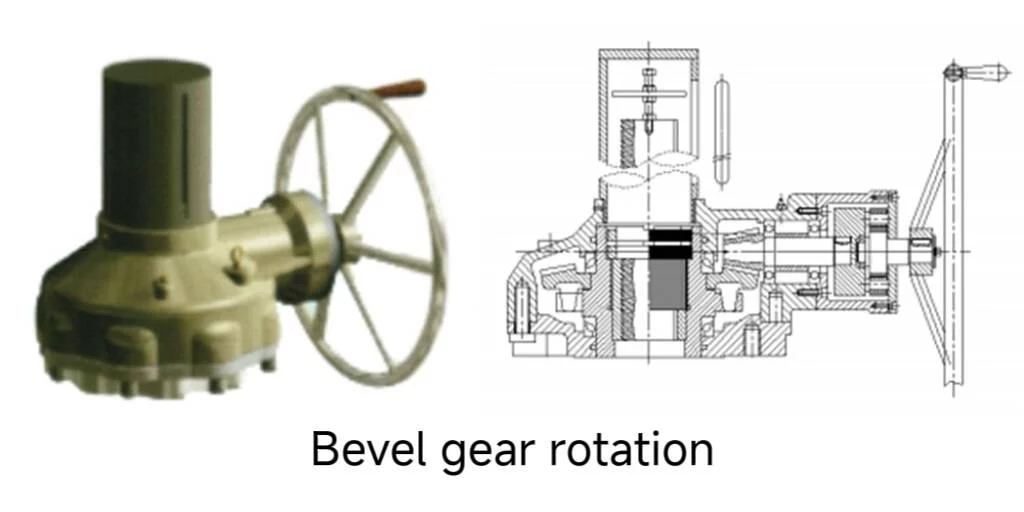

Manual: Small diameter handwheel, large diameter bevel gear.

Electric: Suitable for automation requirements and remote control.

Pneumatic: Suitable for fast opening and closing requirements.

Conclusion

The selection of bellows gate valve is not only about choosing a suitable device, but also the key to ensuring the stable and long-term operation of the pipeline system. By comprehensively considering factors such as installation size, medium characteristics, valve structure and control method, you can choose the most suitable product to avoid later failures and losses. I hope that the sharing of this article can help you make more scientific and reasonable valve selection in practical applications. If you have any questions or need further consultation, please feel free to contact us and look forward to interacting and communicating with you.