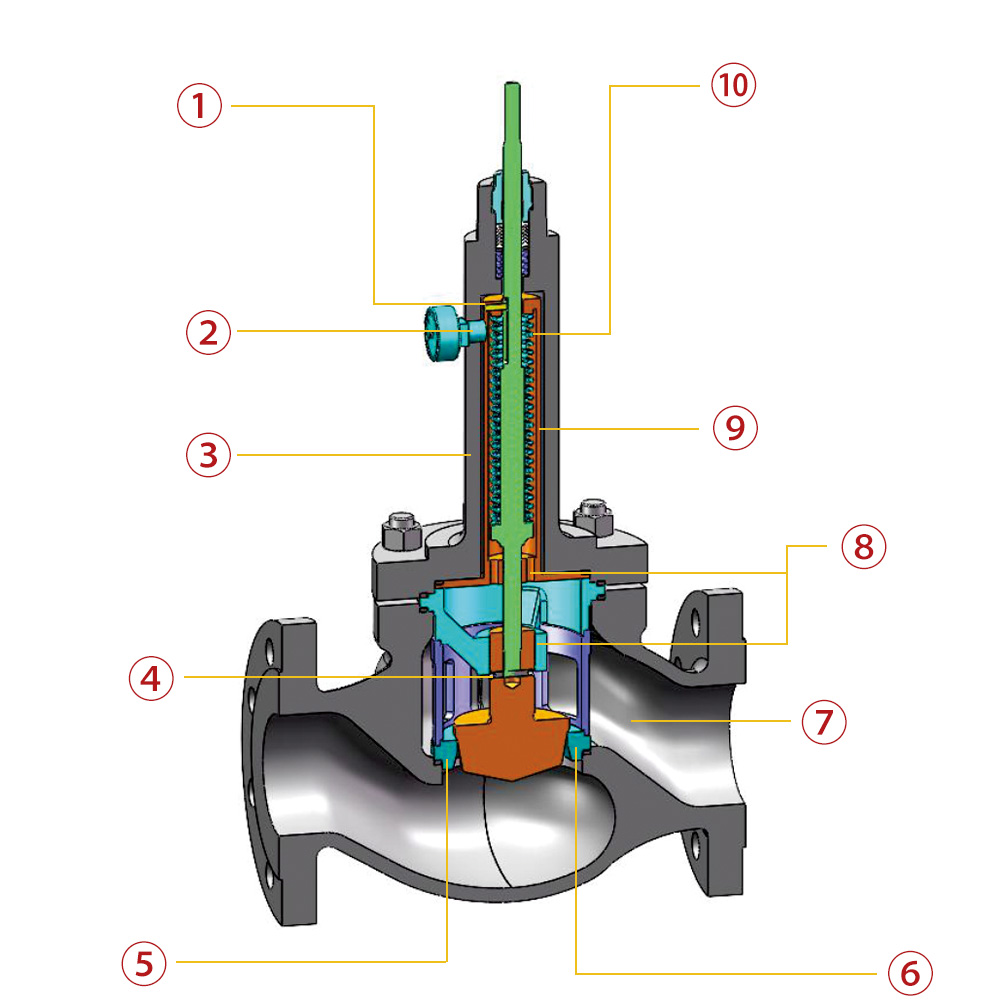

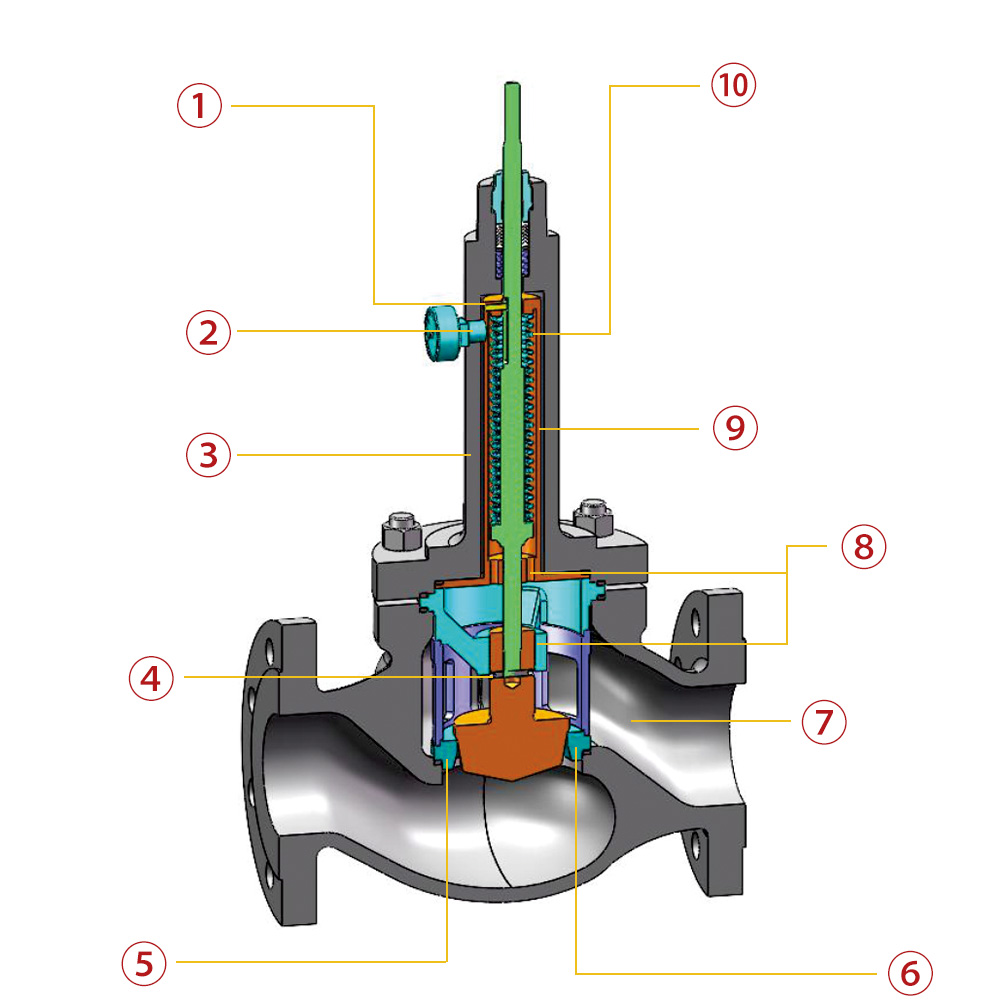

5.1 Single-seat control valve

①. Bellows anti-rotation Structure

The keyway on the valve stem is matched with the pin of the bellows sleeve. Forcing the bellows to move along the axis to prevent damage and increase the service life of the bellows.

②. Bellows failure detection structure

A pressure gauge or pressure sensor can be connected to the detection port on the valve bonnet for real-time monitoring of bellows leakage.

③. Single bonnet structure

Lower external leakage risk.

④. Thread + Pin Connection Structure

The plug and stem are closely connected, and there is no relative moving gap. Effectively prevent stem fatigue and fracture caused by the relative swing of the plug and stem.

⑤. Sealing gasket quantitative compression structure

Prevent the gasket from being overly compressed to achieve durable sealing without leakage.

⑥. Up-pressure valve seat structure

By loosening the valve bonnet bolts, the internal components of the valve can be removed one by one, allowing for quick maintenance and replacement of the valve seat and internal components on-site,thus saving the user’s maintenance time.

⑦. Bellows and flow channel separation structure

Prevent the medium from directly impacting the bellows, improve the service life of the bellows.

⑧. Double-guided valve plug structure

The valve core operates smoothly, not prone to vibration and sticking,ensuring higher regulating precision.cc

⑨. Bellows structure with protective armor

Protects the bellows during handling, installation, and operation. Without bonnet parts, more convenient and fast to replace.

⑩. Bellows external pressure bearing structure

Provide stable pressure load for bellows, reduce movement and increase the maximum allowable stress, thus improving the bellows service life and valve operation accuracy.

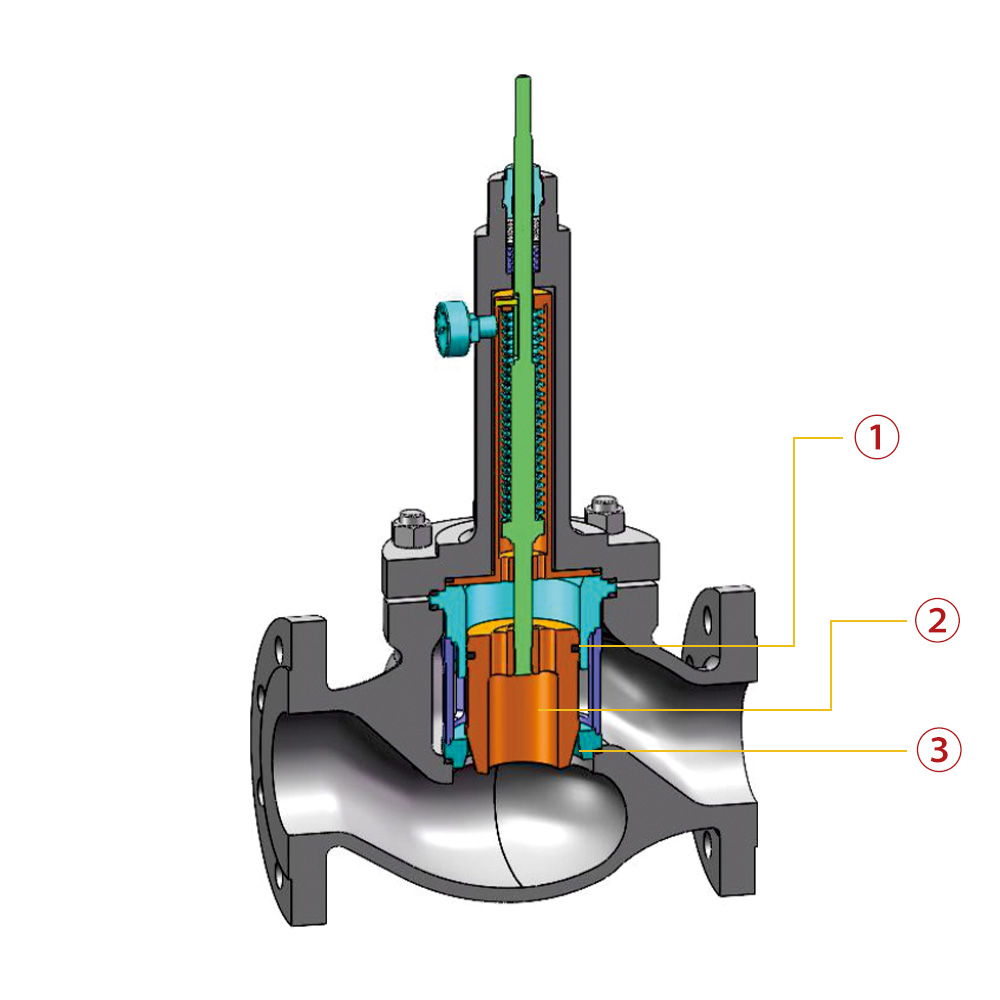

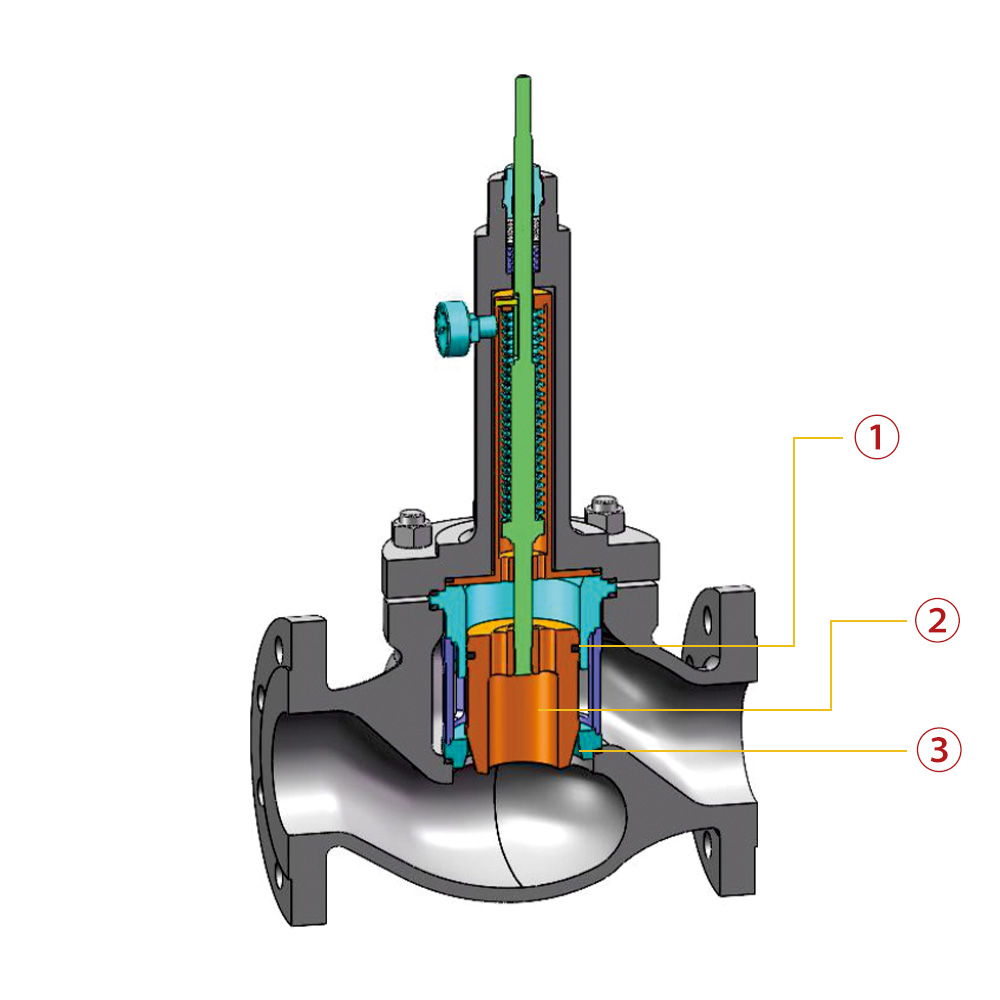

5.2 Balanced Single-Seat Bellows Control Valve

①. Wear-resistant piston ring seal structure

The wear-resistant piston ring still has self-lubricating at temperatures above 200°C, making the valve not easy to stretch and stick during the long period regulating process, maintaining a seal class above level IV .

②. Balanced single-seat structure

Low thrust overcomes the large pressure difference, has better performance of overcoming differential pressure.

③. Spherical valve plug structure

The throttling orifice is uniformly distributed on the surface of the valve core, allowing the medium to flow smoothly and stably, thus has higher regulating precision.