Description

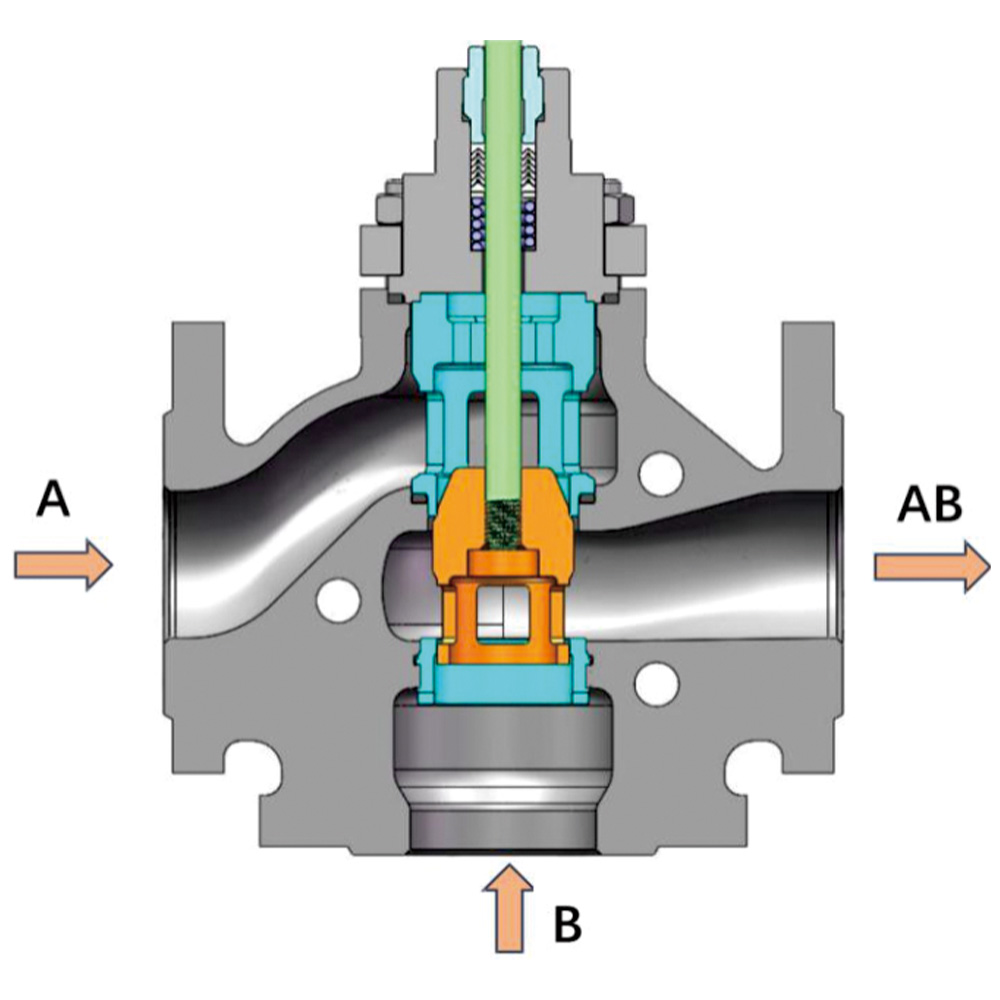

In the heating field, the three-way control valve is a common fluid control component that can replace two two-way control valves to regulate temperature and flow rate. These valves can be categorized as either combination flow and diversion type according to their functionality. Common issues with three-way control valves include difficulty in disassembling and replacing valve seats, packing wear and leakage, poor adjustment accuracy, stem breakage or detachment, and large leakage,which cannot meet operational requirements, lead to emergency in severe cases shutdowns, resulting in substantial losses for users.

Regarding above potential hazards, the Newton R&D team conducted in-depth users’ sites and extensive information gathering regarding operational conditions, as well as technological breakthroughs and through extensive validated tests and experiments making the designs, manufacturing, and batch deliveries of the V6000 series three-way control valves fully meet users’ requirements.

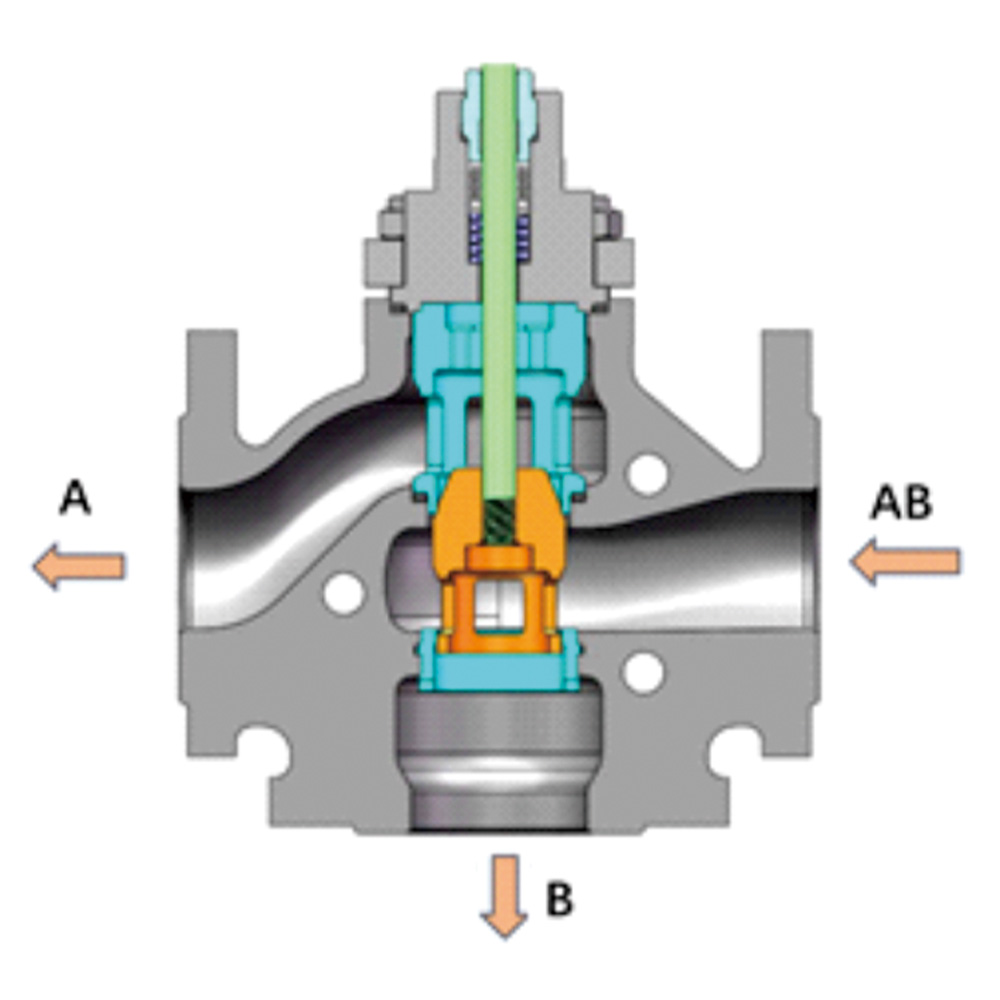

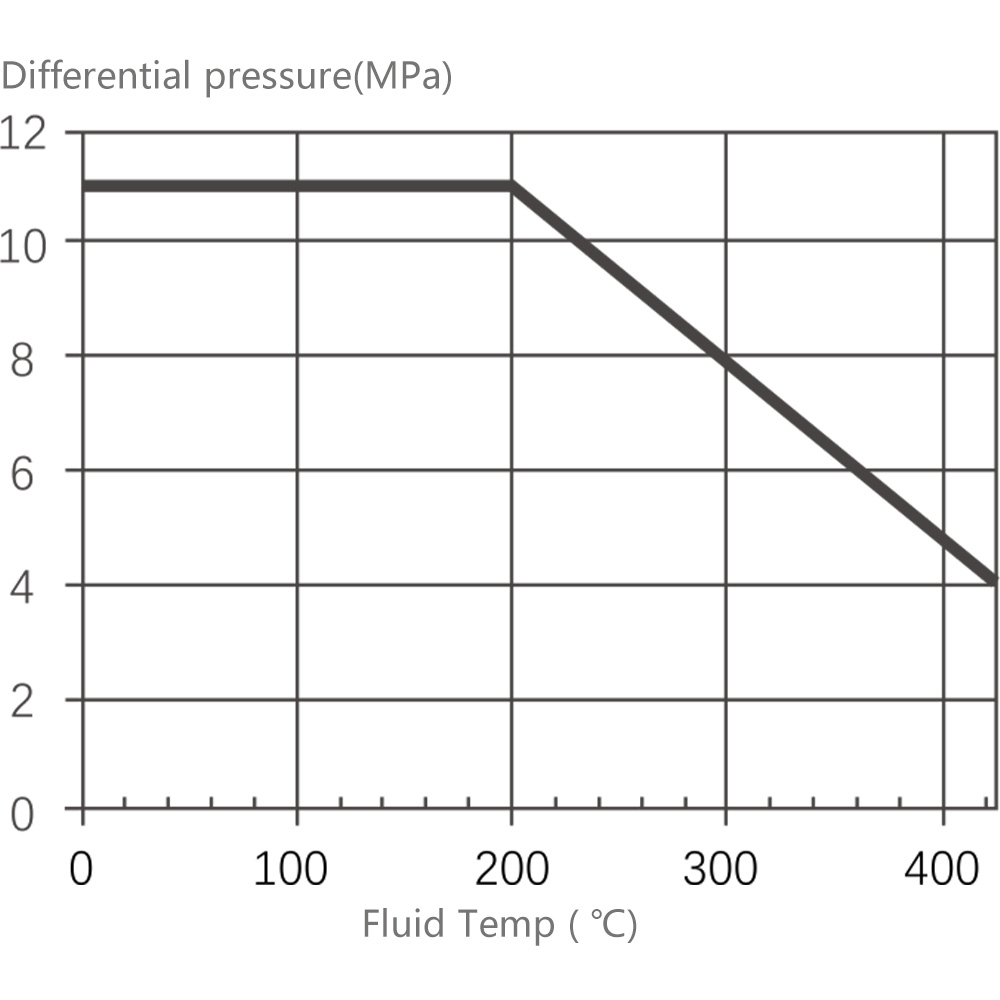

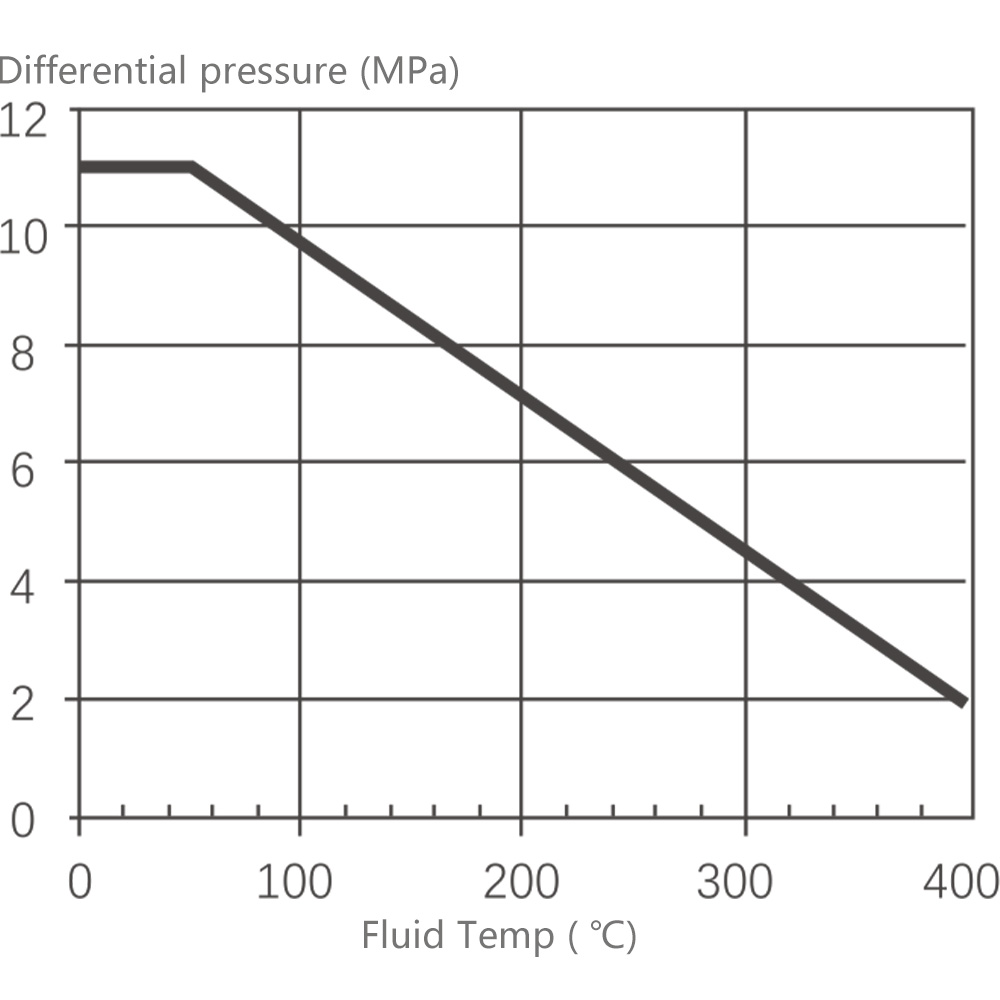

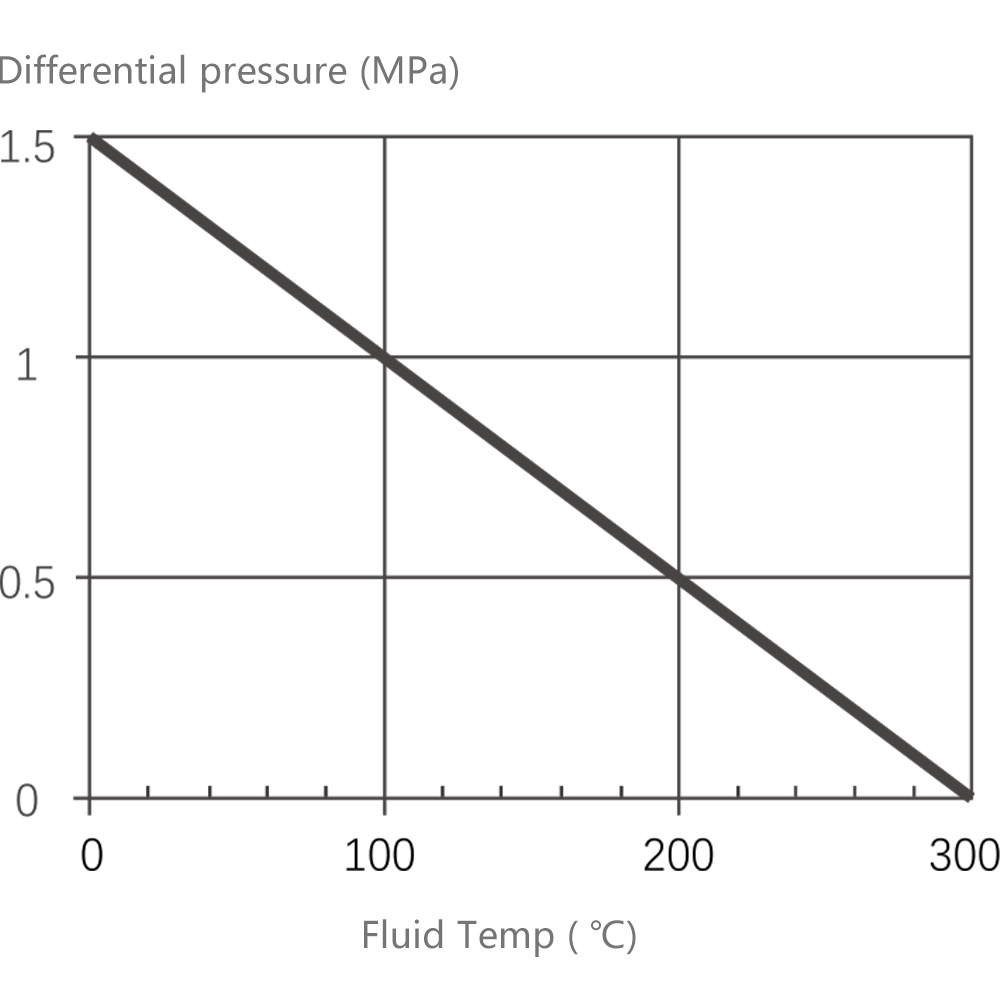

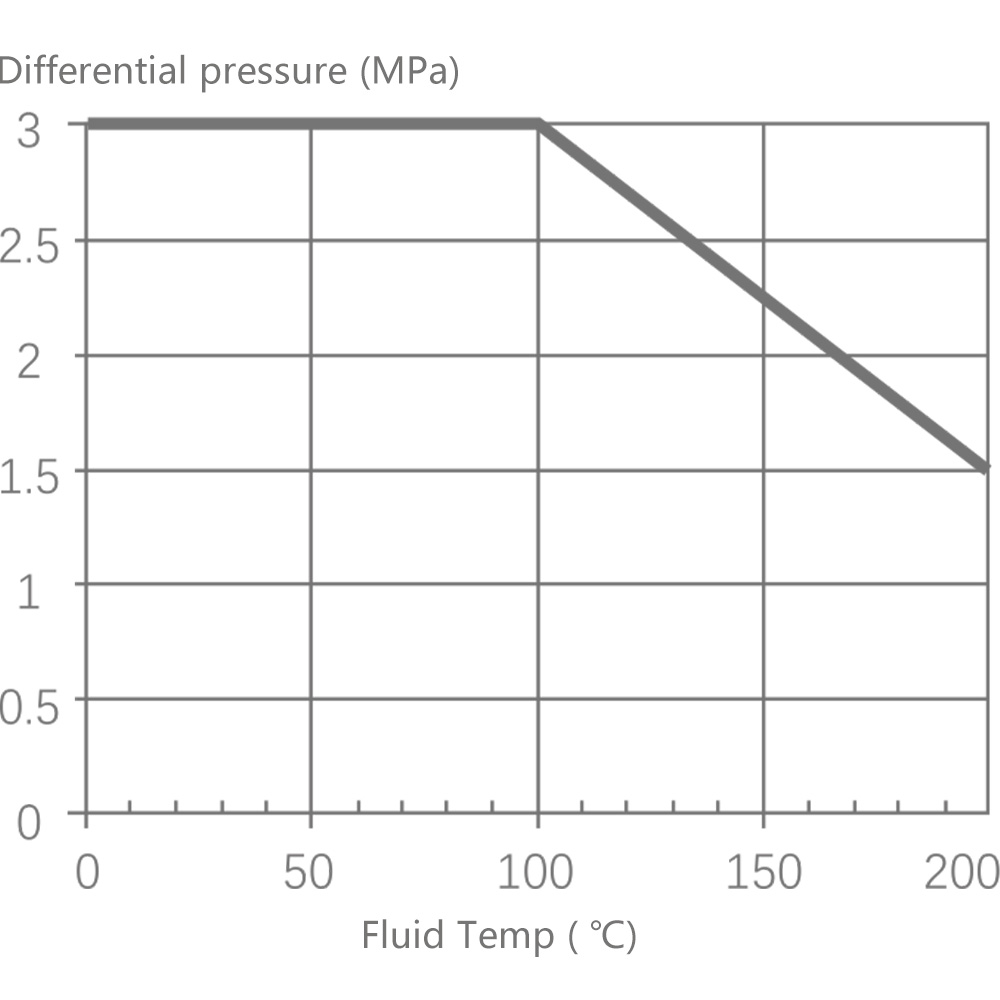

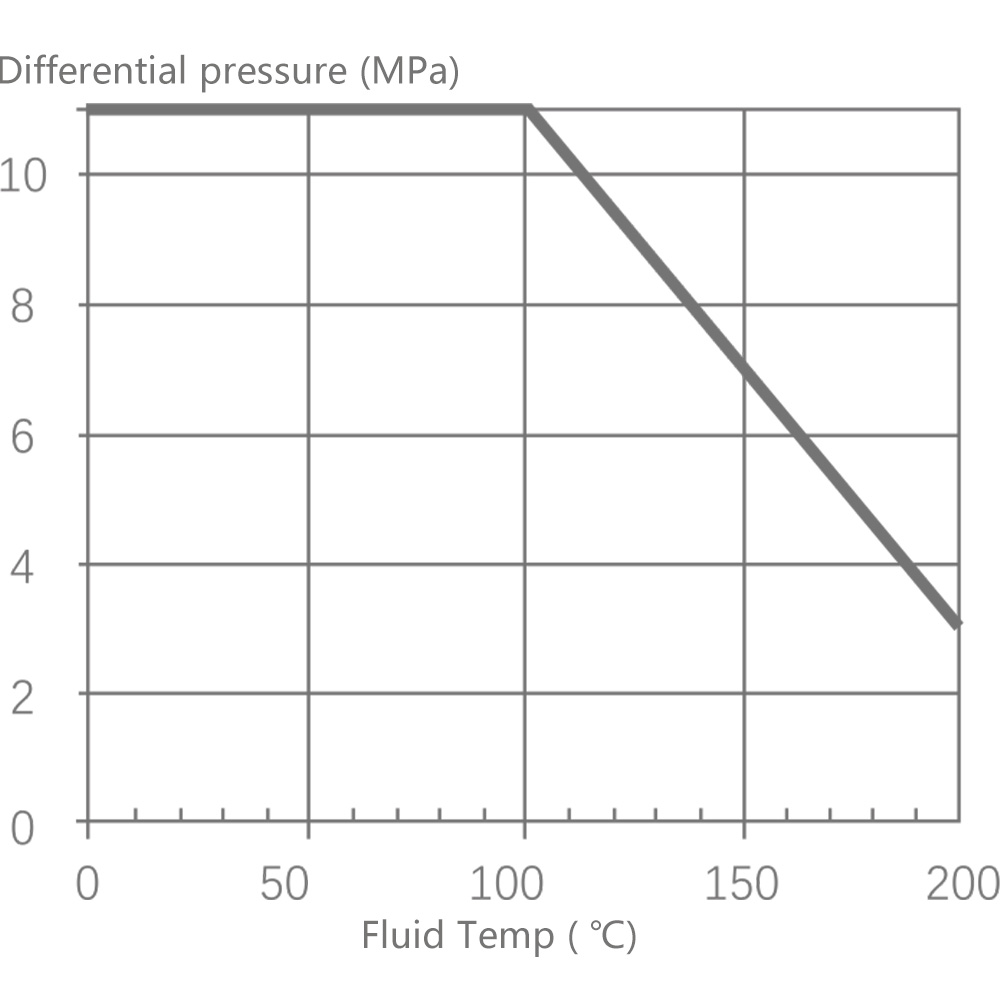

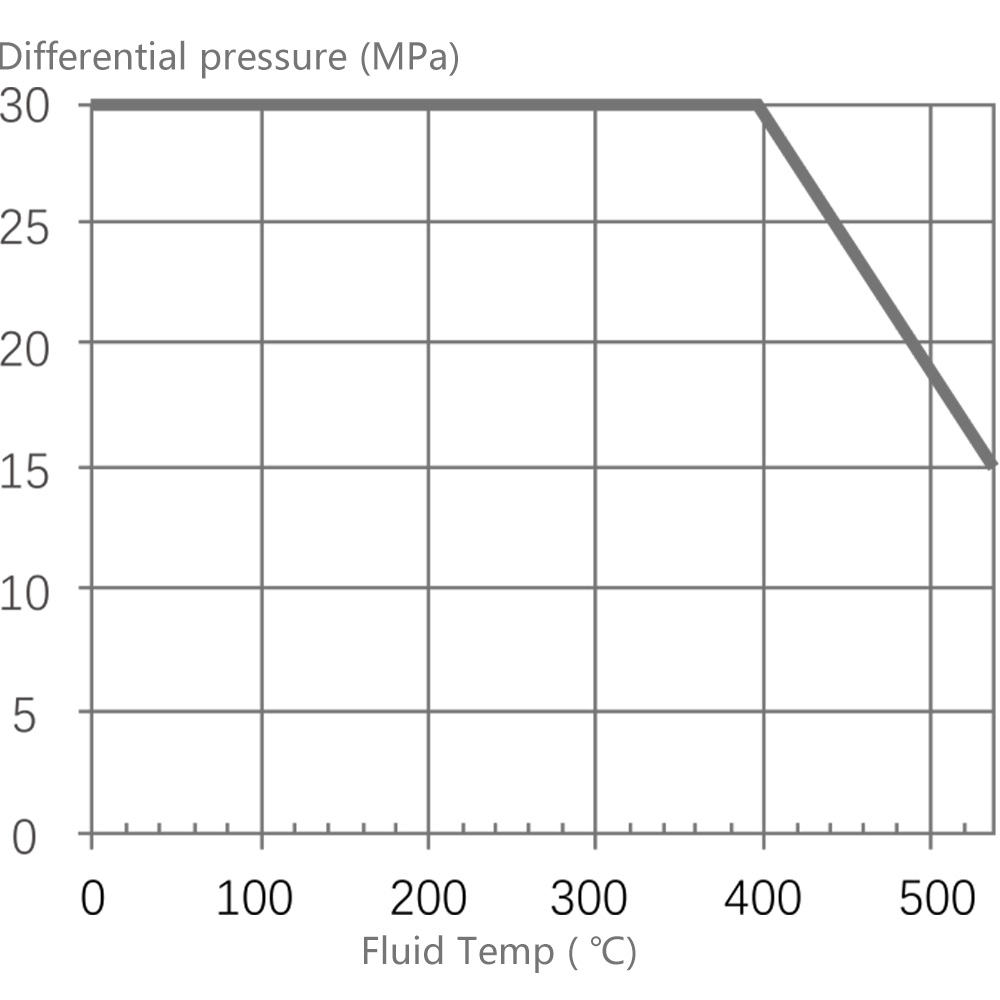

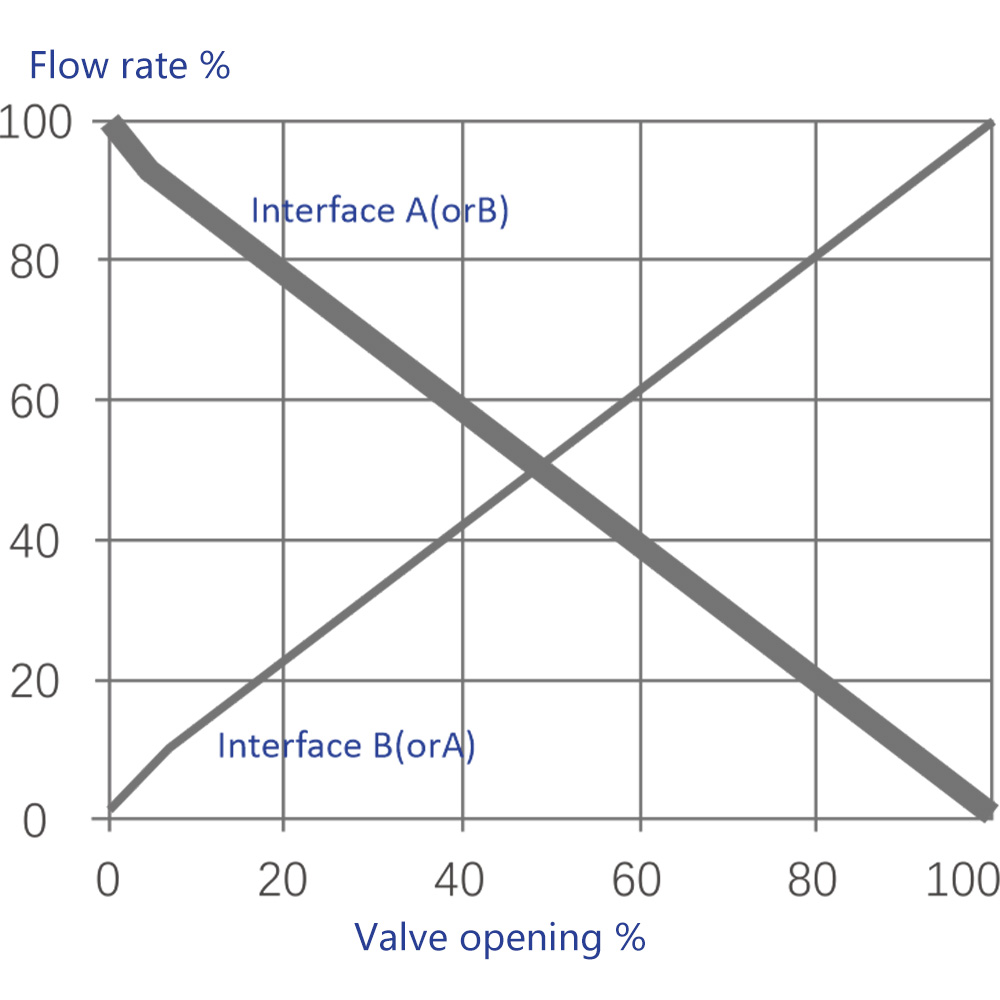

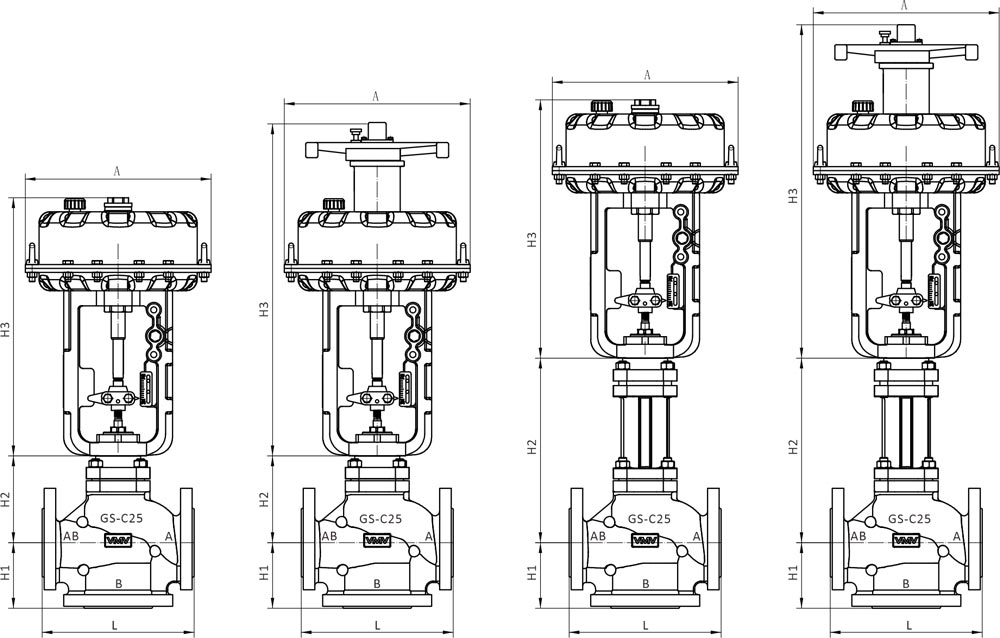

Three-way diversion type(DN≤65)

Three-way diversion type(DN≤65)