Description

Working Principle

Based on the differential density of steam and liquid.

Features

- The body and cover are all made of forged steel/cast steel.

- Internal parts are all made of stainless steel and added with anti-wear allowance, extend trap life.

- U-shaped flow channel design, to achieve water sealing effect, no leakage of steam.

- Reliable flexible closure system with patented technology, no steam leakage.

- Install anti-water hammer device.

- Built-in check valve, suitable for superheated steam environment.

- Built-in filter allows the trap to work in a clean environment.

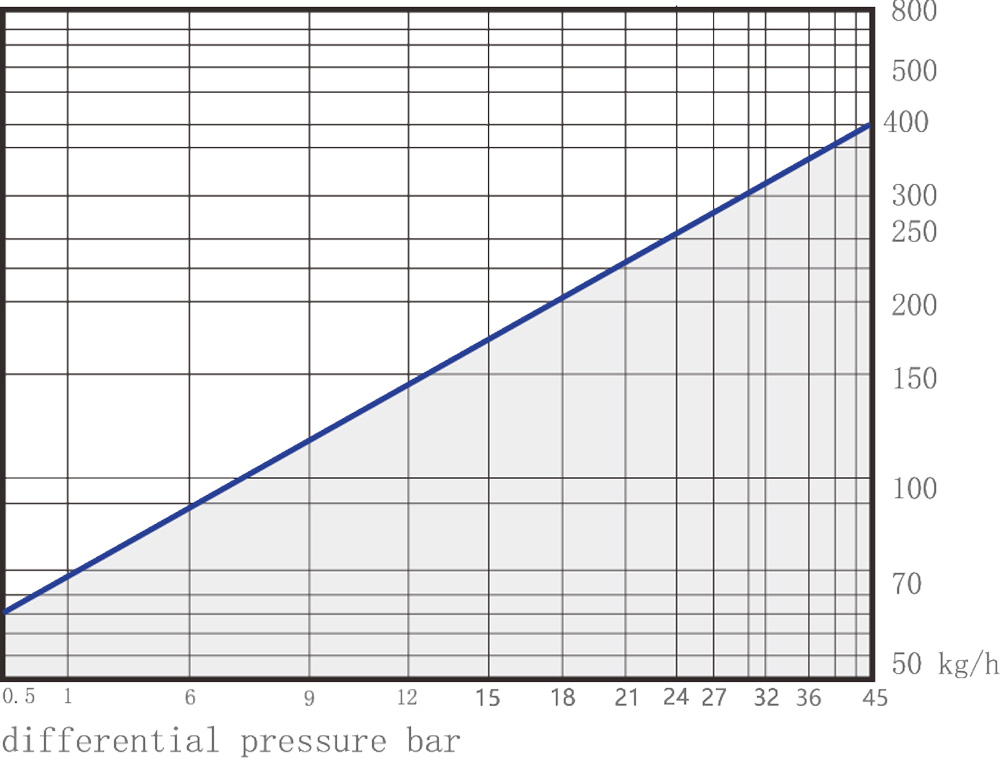

- Select different displacement curves according to the pressure difference to increase the displacement.

- The back pressure rate is as high as 90% or more.

- After the steam is stopped, the condensed water can be removed by opening the screw plug to prevent damage to the trap due to low temperature freezing.