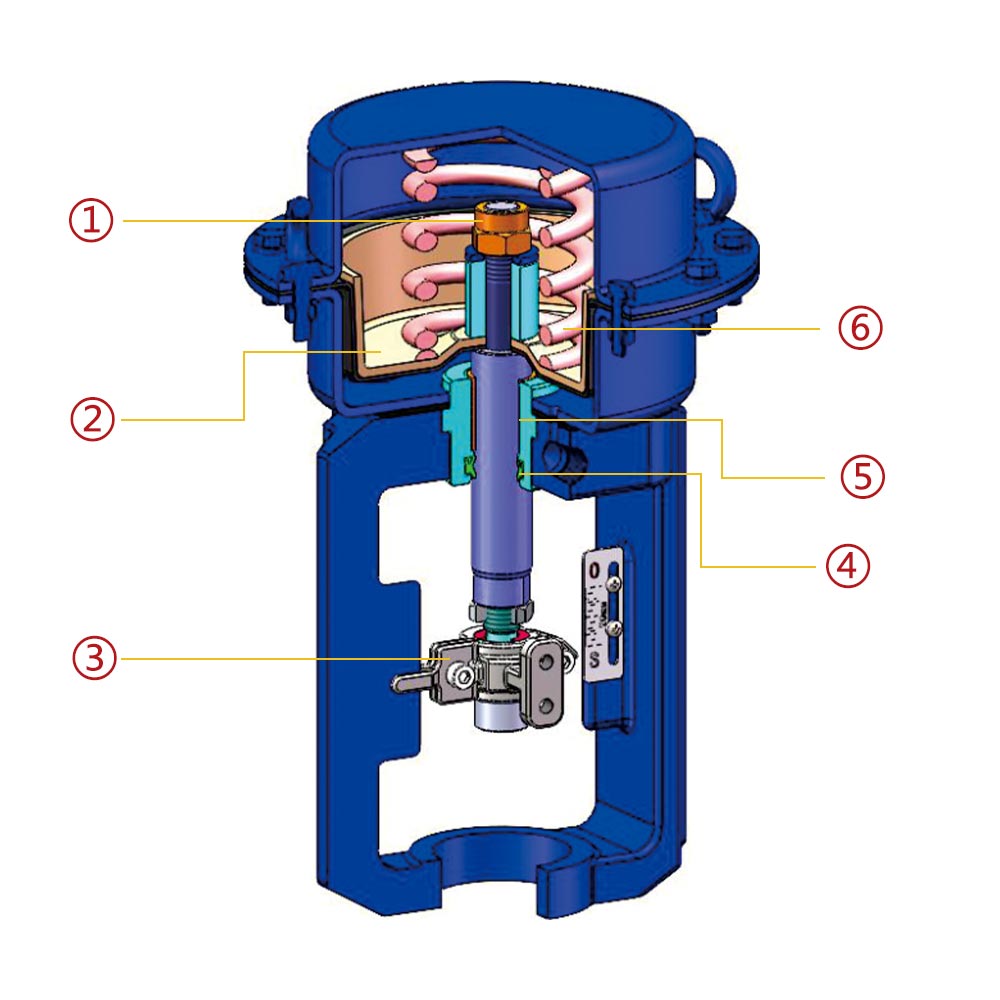

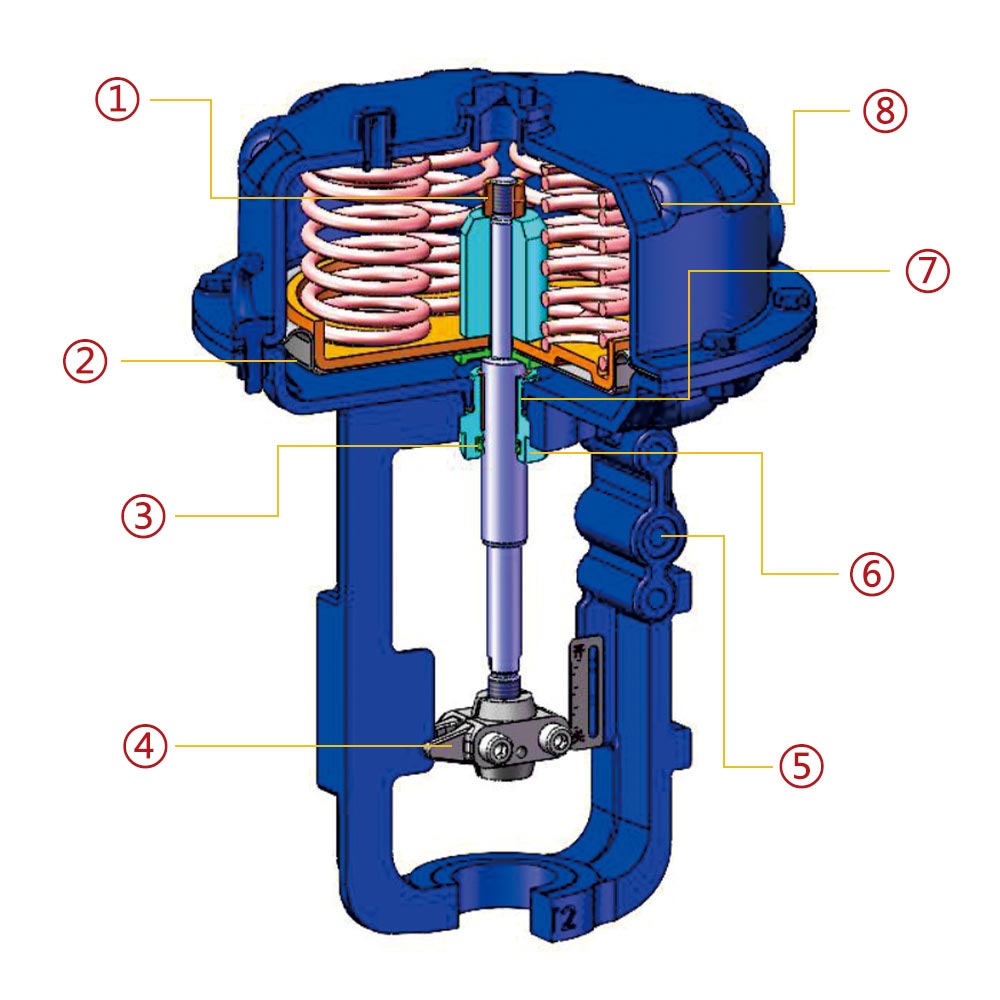

Description

The MT series pneumatic diaphragm actuator is designed with a single-spring or multi-spring structure, providing an axial output thrust. It is compact in structure, light in weight, small in size, performs highly, has a long service life, and delivers a significant output thrust. It is used in conjunction with GLOBE control valves, globe valves, and other straightstroke valves, facilitating a tight and easy valve closure.

Working principle: The electrical signal from the control instrument, after being converted into air pressure by the positioner or solenoid valve, is input into the diaphragm chamber. This pressure acts on the diaphragm to generate thrust, causing the output shaft to move.

MT actuator has excellent versatility and interchangeability. In the field, the action mode can easily be reversed. by simply flipping the upper and lower diaphragm chambers, Its unique design, which requires no external air supply tubing, means air is supplied to the positioner and actuator through holes in the mounting bracket,eliminating the need for external tubing. Compared to traditional designs, this arrangement is more reliable and requires less space for control valves assembly. This method ensures a safe air supply to the actuator and significantly simplifies the assembly process of the positioner.