Description

Product Features

The valve parts in contact with the medium are strictly low-temperature treated according to the requirements of the specification before finishing to ensure that the valve parts can fully withstand the expansion and contraction caused by temperature change, and the structure of the valve seat part will not be permanently deformed due to temperature changes.

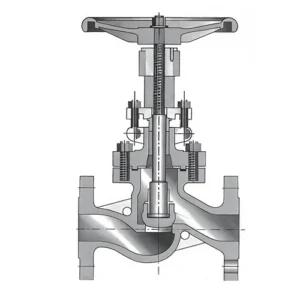

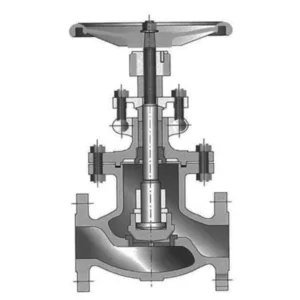

Adopt long-necked bonnet structure to protect stuffing box.

Use conical disc that can maintain a reliable seal regardless of temperature changes.

The upper sealing seat is welded with CoCrW and create a certain hardness difference between the sealing surfaces to avoid the damage.

The valve seat and disc sealing surface cladding with CoCrW.

The surface of the valve stem is nitrided and hardened to prevent surface damage during the opening and closing of the valve from affecting the sealing performance.

The packing can be selected as low-leakage packing according to user’s requirements and meets environmental protection requirements.

Welding sleeves can be customized if needed.

Insulation board (drip board) can be customized if needed.

1、Design standard:

BS 6364 Cryogenic valves

MESCSPE 77/200 Valve specifications for cryogenic media

ISO 15848 Fugitive emission test for valves

2、End connection:

ASME B16.5 Pipe flanges and flange fittings

ASME B16.25 Butt welding end

3、Test and inspection:

API598 Technical conditions for cryogenic valves

BS 6364 Technical conditions for cryogenic steel valve castings

MESC SPE 77/200 Valve specifications for cryogenic media

ISO 15848 Fugitive emission test for valves

Main parts material

| Parts name | Material | ||||||

| -46℃ | -101℃ | -196℃ | |||||

| Body | ASTM A352-LCB A350-LF2 |

ASTM A352-LCC |

ASTM A352-LC3 A350-LF3 |

ASTM A351-CF8 A182-F304 |

ASTM A351-CF8M A182-F316 |

ASTM A351-CF3 A182-F304L |

ASTM A351-CF3M A182-F316L |

| Bonnet | ASTM A352-LCB A350-LF2 |

ASTM A352-LCC |

ASTM A352-LC3 A350-LF3 |

ASTM A351-CF8 A182-F304 |

ASTM A351-CFBM A182-F316 |

ASTM A351-CF3 A182-F304L |

ASTM A351-CF3M A182-F316L |

| Bracket | ASTM A352-LCB A350-LF2 |

ASTM A352-LCC |

ASTM A352-LC3 A350-LF3 |

ASTM A351-CF8 A182-F304 |

|||

| Valve stem nut | ASTM A439-D2 | ||||||

| Pressure plate | ASTM A352-LCB A350-LF2 |

ASTM A352-LCC |

ASTM A352-LCB A350-LF2 |

ASTM A351-CF8 A182-F304 |

|||

| Handwheel | Malleable Cast Iron | ||||||

| Sleeve | ASTM A276 304 | ASTM A276 304 | |||||

| Gasket | Class300~600LB,Stainless steel spiral wound gasket Class900~1500LB,Metal gasket | ||||||

| Packing | Flexible graphite | ||||||

| Gland | Carbon steel | ASTM A276 304 | |||||

| Handwheel nut | Carbon steel | ASTM A276 304 | |||||

| Stud | ASTM A193 L7 |

ASTM A320 L7 |

ASTM A193 B8 | ||||

| Nut | ASTM A194 4 |

ASTM A3204 |

ASTM A194 8 | ||||

| Eyebolts | ASTM A193 L7 |

ASTM A320 L7 |

ASTM A193 B8 | ||||

Product range

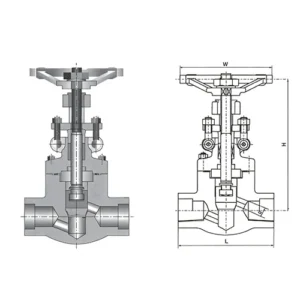

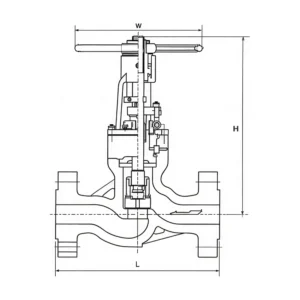

Nominal size:1/2″–36″ DN15-DN900

Pressure:ANSI/ASME150Lb-1500Lb PN16-PN250

Applicable temperature:-29 to -196℃

Operation mode: handle, gear, electric actuator, pneumatic actuator.