As we all know, a steam trap is a valve that can automatically discharge condensate, air and other non-condensable gases from steam pipes and steam-using equipment and prevent steam leakage. Whether it works properly or not greatly affects the performance and efficiency of steam-using equipment, including boiler supporting equipment, and also affects the life of these equipment.

The condensed water produced in the steam tracing pipe, steam-water separator, secondary steam tank, and in the process of using steam for heating, drying, heat preservation, heating, disinfection, distillation, concentration, cooking, heat exchange, heating, air conditioning, etc., must be removed by steam traps. It can be seen that steam traps are the most widely used energy-saving products.

It is very important to understand its working principle and select and use it correctly. This article will focus on the selection basis and method of steam trap for reference by colleagues.

一、Functional requirements of steam trap

1.Reduce the steam consumption of the steam trap itself

The steam consumption of the steam trap itself generally refers to steam leakage, which is the sum of the steam required for the steam trap to operate and the heat loss.

2.Rapidly discharge the air and low-temperature condensed water in the equipment when starting up

Quickly discharge the air and low-temperature condensate in the equipment at the start-up, thereby shortening the preheating operation time.

When steam is first supplied, the steam transmission pipeline and steam-using equipment are full of air. If they are not discharged, steam cannot be supplied.

In addition, when the steam transmission pipeline and steam-using equipment are heated to the steam temperature, the initial low-temperature condensate produced must be quickly discharged so that the equipment can operate normally in a short time. This is an important condition for improving production efficiency.

Especially in the case of intermittent production, since the preheating time is shortened, the operation time of each operation is also shortened, which can ultimately increase production.

3.Rapidly discharge the condensed water generated in the steam-using equipment

Quickly discharge the condensate generated in the steam-using equipment to keep the heating efficiency of the steam-using equipment at the best state, so that the condensate in the equipment does not form a stagnation, and maximize the steam space in the equipment, so that the highest heating efficiency can be maintained at all times.

Once the steam trap cannot fully play its role, due to the stagnation of condensate, not only the performance of the steam-using equipment is greatly affected, but sometimes even the production equipment is completely paralyzed.

二、How to detect whether the steam trap is working properly

(I)The importance of selection:

The reasonable selection of steam traps is very important, and it is a prerequisite for using the traps well. In actual work, we often encounter customers who confuse steam traps with general valves, and ask how much a certain type and specification of steam trap costs when inquiring. This is a simple way to think that the connection diameter of the steam trap represents everything about the steam trap.

After we have a detailed understanding of the structure, working principle, and purpose of the steam trap, we will know that the working pressure difference of the steam trap, the drainage volume per unit time under the pressure difference, the maximum allowable operating pressure, the maximum operating temperature, the specifications and standards of the connection end, the structural length, the installation direction, etc. are all important parameters for selection and inquiry.

(II)Selection steps and basis:

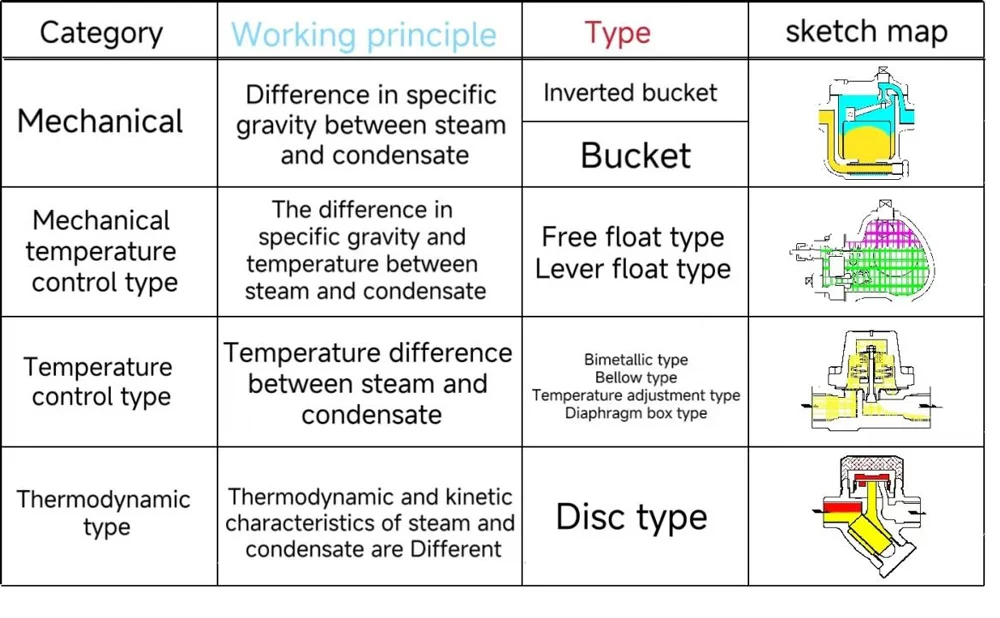

The first is the heating temperature requirement. Select the type of steam trap according to the heating temperature requirements of the equipment used. If the fastest heating speed is required and the temperature control requirements are strict (condensate cannot be accumulated in the heating equipment), a mechanical steam trap that can discharge saturated water should be selected. On the contrary, if rapid heating is not required, the temperature control is not strict, and a certain amount of condensate is allowed to accumulate and its sensible heat is used, a thermostatic steam trap should be selected, and a thermodynamic steam trap should be selected for overheating.

The second is the working pressure difference of the steam trap. When selecting a steam trap, the steam trap cannot be selected based on the nominal pressure, because the nominal pressure indicates the pressure level that the steam trap shell can withstand, and the nominal pressure of the steam trap is very different from the working pressure difference.

Therefore, it is necessary to select a suitable steam trap according to the operating pressure of the equipment or pipeline steam. Make the highest working pressure difference of the steam trap cover the operating pressure of the equipment or pipeline steam. The working pressure difference of the steam trap refers to the difference between the pressure before the steam trap and the back pressure at the steam trap outlet.

The calculation method of the back pressure behind the steam trap is: when the condensate behind the steam trap is discharged into the atmosphere, the outlet back pressure of the steam trap is zero. If the condensate discharged from the steam trap is collected centrally, the outlet back pressure of the steam trap is the sum of the resistance of the return pipe, the lifting height of the return pipe, and the pressure in the secondary evaporator (return tank).

The third is the pressure-temperature rating and nominal pressure of the steam trap shell material. The nominal pressure determines the design of the shell wall thickness. The same material has different pressure-temperature ratings under different nominal pressures.

The fourth is the calculation of the drainage capacity (displacement) of the steam trap. When selecting a steam trap, the drainage capacity of the steam trap must be selected according to the condensate production of the equipment per hour (approximately the steam consumption) multiplied by the selection ratio of 2-3 times as the maximum condensate volume. Only in this way can the steam trap be guaranteed to discharge condensate as soon as possible when starting up and quickly increase the temperature of the heating equipment.

If the steam trap does not discharge enough energy, the condensate cannot be discharged in time, which reduces the thermal efficiency of the heating equipment. When the steam heating equipment starts to deliver steam, the equipment is cold and filled with air. The steam trap needs to quickly discharge the air and then discharge a large amount of low-temperature condensate to gradually heat up the equipment, and then the equipment enters normal working state.

Why is there a safety factor?

1) The capacity of the steam trap refers to the discharge volume when the condensate is continuously discharged, and almost all steam traps are intermittently discharged during actual operation.

2) The capacity of the steam-using equipment refers to the amount of condensate produced by the equipment during normal operation, and at the beginning of the equipment startup, the amount of condensate produced is much greater than that during normal operation.

3) When there is an error between the actual amount of condensate produced by the steam-using equipment and the indicated steam consumption, the safety factor estimated to ensure the normal operation of the steam trap can also be used.

Recommended safety factors for various equipment:

| Device Name | Applicable safety factor | Device Name | Applicable safety factor |

| Coil Heater | 2 | Still air heating tube | 3 |

| Conditioning kettle | 2 | Gluing and molding machine | 3 |

| Steam separator | 2 | Pressurized Heater | 3 |

| Closed feedwater heater | 2 | Pressure tank | 3 |

| Dyeing trough | 2 | Air forced cooling plate heater | 5 |

| Drum dryer | 8 |

Connection size of steam trap

After the process conditions of the steam trap are determined, the specifications and dimensions of the steam trap are selected according to the working pressure difference before and after the steam trap, the pressure-temperature rating, the drainage volume, and the technical parameters of the steam trap manufacturer.

You cannot randomly select steam traps of the same size according to the connection size of the equipment. The connection diameter of the steam trap cannot represent the size of the drainage volume. The drainage capacity of steam traps of the same diameter may vary greatly.

Therefore, when selecting a steam trap, it is necessary to select a steam trap according to the process conditions of the equipment and refer to the parameters provided by the steam trap manufacturer to select the steam trap.