Description

Working Principle

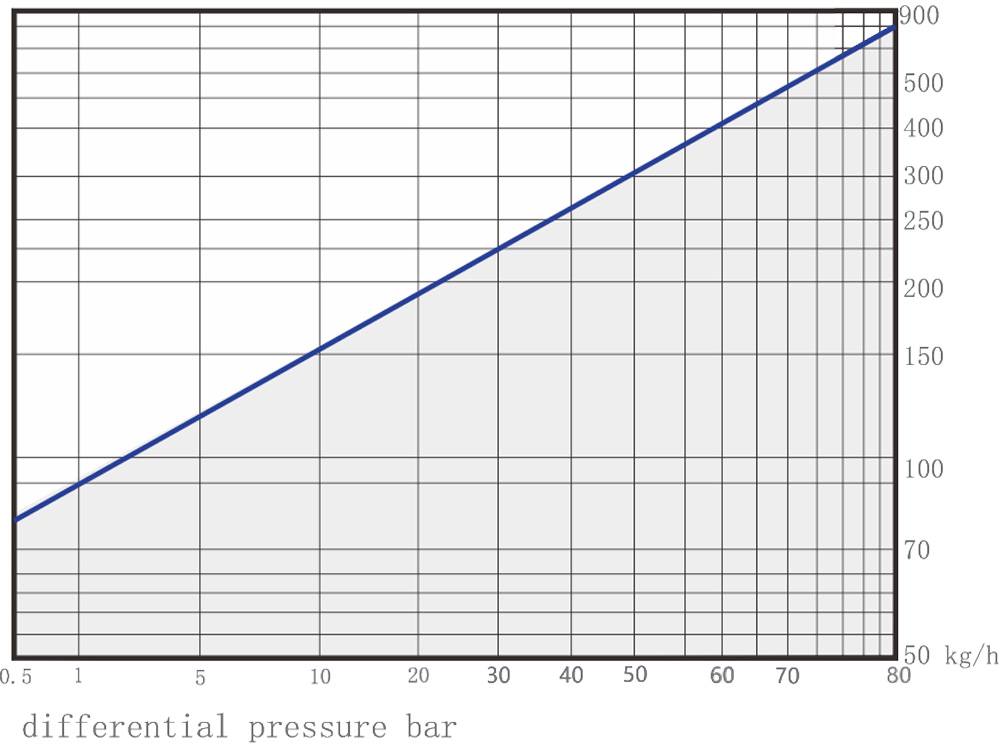

Depends on the difference of steam and liquid flow rate.

Features

- The Valve body and valve bonnet are all made of forged steel.

- The disc and seat are made of special stainless steel, which is heat treated and aging treatment, no deformation and wear resistance under high temperature and high pressure, improve the service life of the trap.

- Stainless steel insulation cover to isolate and slow down heat loss and prevent the trap from emptying up phenomenon.

- The fluid channel of the internal structure is designed strictly according to Bernoulli’s equation, and the structure is reasonable.

- Built-in filter makes the trap work in a clean environment.

- The back pressure rate is as high as 80% or more.