A swing check valve is a valve that automatically prevents fluid backflow. The main function is to prevent the backflow of the medium in the pipeline, ensure that the medium can only flow in one direction, and avoid accidents. It is suitable for chemical, petroleum, power stations and other fields. It is often used as a bottom valve for pumping devices to prevent water backflow. It can also be used in combination with a stop valve to play a role in safety isolation.

What is the difference between a swing check valve and other check valves?

Structure

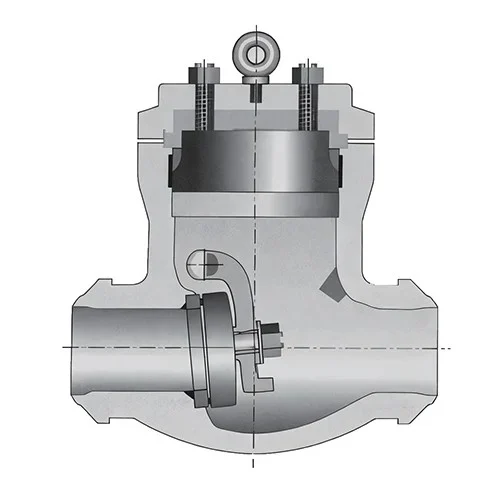

Swing check valve: The valve disc is a hinged structure. The valve disc is connected to the valve body through a pin shaft and can rotate around the axis. The pin shaft passes through the outer edge of the sealing surface of the valve plate and is outside the flow channel. There are different structural forms such as single disc, double disc and multi-disc.

Other check valves: Taking the lifting check valve as an example, it adopts a vertical motion valve disc design. The valve disc moves vertically along the valve seat in the valve body and does not have a structure that rotates around the axis.

Working method

Swing check valve: The valve disc is opened and closed by relying on the force of the medium flow to rotate around the axis. When the medium flows forward, the valve disc is pushed open; when the medium flows backward, the valve disc quickly rotates around the axis and closes under gravity or fluid back pressure.

Other check valves: such as lift check valves, which rely on fluid pressure and gravity to open and close. When the medium flows forward, the valve disc is lifted up, and when the medium flows backward, the valve disc falls vertically and closes under the action of gravity or spring.

Features

Swing check valve: It has the characteristics of small flow resistance and flexible opening and closing, but the impact force is large when closing, which may cause water hammer phenomenon, and usually needs to be used with slow closing device.

Other check valves: Like lift check valves, they have excellent sealing performance, but have high requirements for fluid cleanliness, because if there are impurities in the medium, it may affect the vertical lifting and sealing effect of the valve disc.

Swing check valves mainly control flow in the following ways:

Flow control during forward flow

Opening process: When the fluid flows in from the inlet end of the valve and the pressure exceeds the opening pressure of the valve disc (usually determined by the valve disc gravity, spring force and fluid resistance), the valve disc is pushed open. As the inlet pressure increases, the valve disc gradually opens to the maximum position, and the fluid passes smoothly.

Flow regulation: The opening of the valve disc depends on the difference between the inlet fluid pressure and the outlet fluid pressure (i.e., pressure drop). In a stable forward flow, the greater the pressure difference, the greater the valve disc opening, and the greater the flow allowed to pass. Since the flow channel design of the swing check valve is relatively spacious and the fluid resistance is small, the flow is less restricted and is suitable for large flow conditions.

Flow control during reverse flow

Closing process: When the fluid flows in the reverse direction, the outlet pressure is greater than the inlet pressure. The reverse fluid pressure pushes the valve disc to close quickly, and the valve disc fits tightly to the valve seat under the action of its own gravity and fluid pressure to form a seal to prevent the fluid from flowing back.

In summary, the swing check valve mainly controls the flow through the automatic opening and closing of the valve disc, allowing the forward fluid to pass and preventing the reverse flow. Its flow control mainly depends on the fluid pressure difference, and the special structure helps to optimize the closing performance and protect the pipeline system.

The swing check valves provided by Newton have been strictly inspected from accessories to finished products to ensure a satisfactory use experience.